AOI automatic optical inspection solution

- Home

- /

- Auto-optical-inspection

Auto Optical Inspection

What ProPowertek can do for you?

ProPowertek is equipped with high-resolution Automatic Optical Inspection (AOI) systems, offering customers inspection services for both thick and thin wafers during incoming and outgoing quality control, as well as inspection after wafer frame mounting.

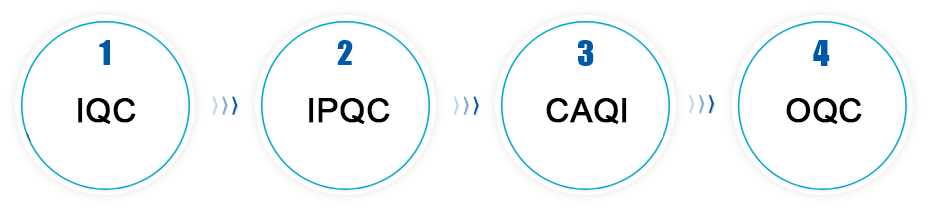

AOI Inspection Process (Based on Requirements)

機台會有固定時間,週期性的進行機台穩定度的檢測,利用控片分別進行各反應腔(Chamber)的測試,在ICP反應腔中會進行蝕刻率測試,在鋁(Al)、鈦(Ti)、鎳釩(NiV)、銀(Ag)則會分別進行沈積率及均勻性的預測試,確定了機台狀況一如往常的平穩後,產品會依照排程開始進入生產,客戶的晶圓在完成入站檢驗 (IQC) 後,客戶可要求進行沈積前DHF清洗或是直接進入濺鍍機,按照客戶指示之種類及厚度及ICP條件,進行金屬沈積 (Sputtering Deposition),完成金屬沈積後,可依客戶需求進行沈積後之氮氣退火,或是直接進行出站檢驗 (OQC)。

The Superiority of ProPowertek

▶ ProPowertek is equipped with AOI (Automatic Optical Inspection) systems that support optical inspection at various stages. IQC (Incoming Quality Control) ensures upstream wafer quality, while in-process and outgoing inspections guarantee process reliability.

▶AOI inspection enables better yield control by integrating upstream or CP (Chip Probing) wafer test maps. This supports downstream packaging by enabling good die selection, helping to reduce packaging costs.

▶ Fully automated AOI reduces human contact, improving reliability and efficiency. It also enhances defect analysis by collecting precise abnormality locations, significantly shortening root cause analysis time.

▶ Our engineering team has diverse backgrounds, including experience in front-end wafer foundries, wafer thinning processes, and back-end packaging houses. This cross-domain expertise enables rapid development, effective problem-solving, and stable mass production support for our customers

Case Sharing

Using AOI to Identify Die Defects and Control Yield

AOI enables detection of common defect distribution patterns, accelerating failure analysis and process convergence.