Wafer cutting process

- Home

- /

- Laser Dicing Process

Laser Dicing Process

What ProPowertek can do for you?

⦁ ProPowertek utilizes laser cutting equipment from the internationally renowned DISCO Corporation, offering a variety of cutting services including Laser Dicing and Laser Grooving. Combined with Blade Dicing, these methods provide flexible wafer dicing solutions suitable for thick metals, high-hardness materials, and third-generation compound semiconductor products.

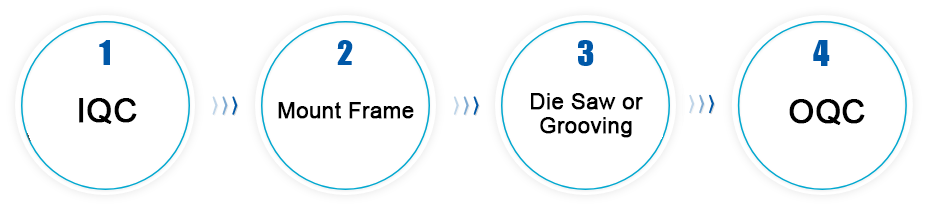

Wafer Dicing Process

機台會有固定時間,週期性的進行機台穩定度的檢測,利用控片分別進行各反應腔(Chamber)的測試,在ICP反應腔中會進行蝕刻率測試,在鋁(Al)、鈦(Ti)、鎳釩(NiV)、銀(Ag)則會分別進行沈積率及均勻性的預測試,確定了機台狀況一如往常的平穩後,產品會依照排程開始進入生產,客戶的晶圓在完成入站檢驗 (IQC) 後,客戶可要求進行沈積前DHF清洗或是直接進入濺鍍機,按照客戶指示之種類及厚度及ICP條件,進行金屬沈積 (Sputtering Deposition),完成金屬沈積後,可依客戶需求進行沈積後之氮氣退火,或是直接進行出站檢驗 (OQC)。

The Superiority of ProPowertek

▶ All wafer dicing (Die Saw) processes utilize a full suite of fully automated DISCO equipment. We possess both blade dicing and laser cutting machines, with the laser systems providing dicing and laser grooving services.

▶ We flexibly address challenges encountered with different materials during the cutting process, offering various combinations such as Blade Dicing (BD), Laser Dicing (LD), Laser Grooving (LG), Laser Grooving (LG) + Blade Dicing (BD), and Blade Dicing (BD) + Laser Dicing (LD).

▶ ProPowertek is equipped with Automatic Optical Inspection (AOI) systems to provide post-dicing die inspection services. Combined with CP wafer testing, we generate a comprehensive wafer map to assist downstream packaging in selecting good dies.

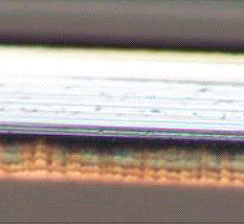

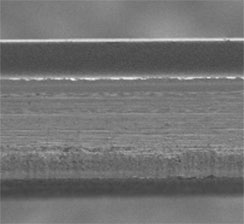

Case Sharing

Backside copper (Cu) metal silicon wafers processed using blade dicing first, followed by laser dicing.

OM Image (side-wall inspection)

SEM Image (side-wall inspection)